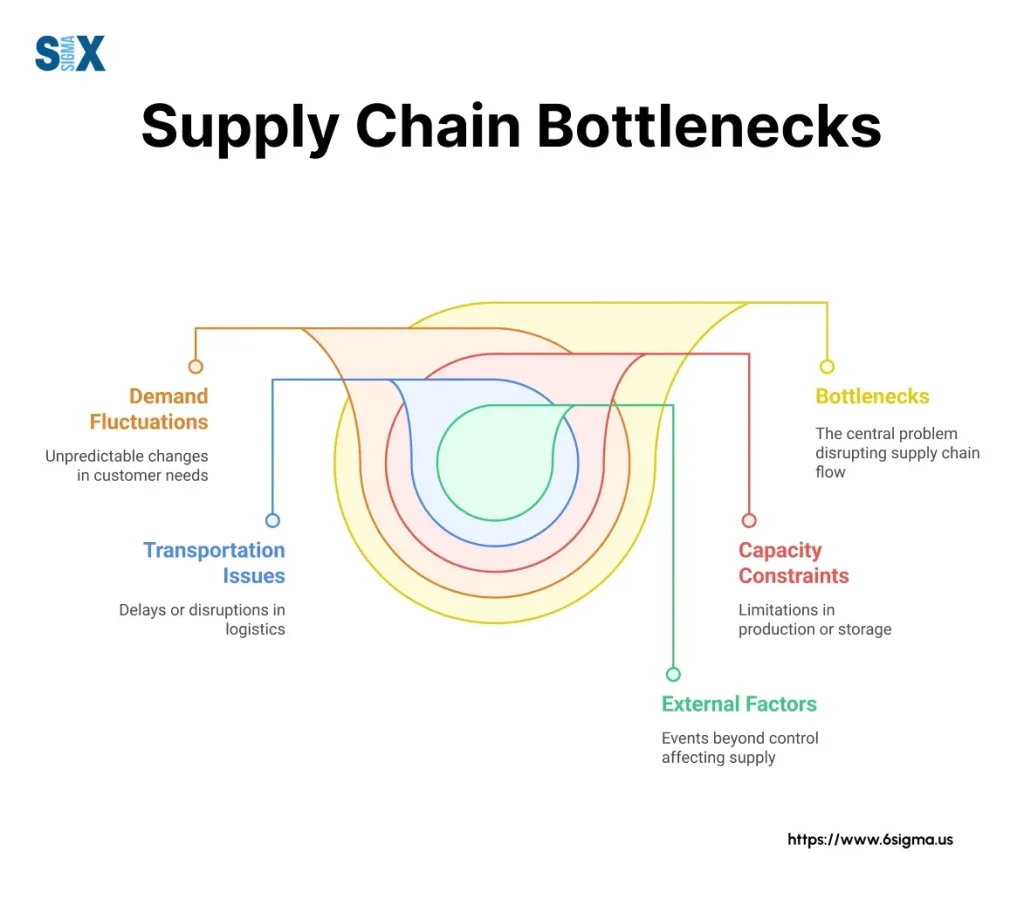

Supply chain bottlenecks are no longer occasional headaches but persistent realities shaping strategic decisions, investment priorities, and risk tolerance across teams, sectors, and geographies, driven by globalization and just-in-time practices. From factories and ports to trucking lanes and warehousing hubs, these logistics bottlenecks push up lead times, inflate costs, and ripple through procurement, production planning, and customer service, affecting budgeting and supplier negotiations. Businesses are steadily building resilience through smarter inventory management strategies and diversified sourcing, seeking flexibility, regional networks, clearer supplier collaboration, and proactive supplier development programs. Greater transparency, real-time analytics, and scenario planning help organizations anticipate chokepoints, enabling proactive rerouting, capacity rebalancing, contingency budgeting, and more accurate costing that preserve performance under pressure. In short, recognizing where bottlenecks form across manufacturing, logistics, and demand planning is the first step toward sustaining service levels in a dynamic global marketplace and maintaining a competitive edge, a framework that supports risk assessment, supply chain finance, and customer experience optimization.

From a wider perspective, the same problems appear as global trade frictions, distribution-network constraints, and recurring supply chain disruptions across suppliers and carriers. Framing the issue this way shifts focus from firefighting to resilience, highlighting end-to-end visibility, flexible sourcing, and robust contingency planning. Speaking in LS-friendly terms such as chokepoints, capacity gaps, and cross-border frictions helps leaders map risk concentration and design smarter networks that absorb shocks. Practical steps like regionalized sourcing, multi-modal logistics, and balanced inventory policies translate these ideas into action, helping preserve service levels while controlling costs.

Navigating Supply Chain Bottlenecks: From Global Challenges to Resilience

Supply chain bottlenecks are not isolated events; they emerge when capacity constraints materialize across transportation, warehousing, and supplier networks. In today’s environment, these chokepoints are amplified by broader global supply chain challenges that ripple through production calendars, inventory levels, and service levels. Recognizing how supply chain disruption travels from a port backlog to a factory floor helps leaders diagnose where to intervene first and how to protect customer commitments. This framing sets the stage for building resilience rather than chasing sporadic fixes.

Understanding the current picture requires looking for signals across several nodes: supplier risk and sourcing constraints, manufacturing downtime, logistics and transit capacity, and demand volatility. When one node slows, downstream processes slow too, expanding cycle times and elevating landed costs. By naming and measuring these bottlenecks—without over-optimizing for a single metric—organizations can translate headlines into concrete actions that reinforce supply chain resilience and inform targeted inventory management strategies.

The implication for leadership is clear: resilience comes from visibility, coordination, and adaptive planning. By linking procurement choices, production scheduling, and transportation modes, companies can soften the impact of recurring disruptions and shorten response times. In this way, the narrative around bottlenecks becomes a blueprint for continuous improvement rather than a series of reactive patches.

Mitigating Disruption: Strategies to Reduce Logistics Bottlenecks and Strengthen Resilience

A practical path to reducing logistics bottlenecks starts with diversification and regionalization of suppliers, paired with deliberate contingency stock for critical items. This approach lowers exposure to localized shocks and supports ongoing operations even when a single node experiences stress. Framing these moves within the broader conversation of global supply chain challenges helps executives justify investments in redundancy, supplier development, and demand shaping—all aimed at sustaining service levels amid volatility.

Beyond supplier structure, increasing supply chain visibility is essential. Real-time inventory visibility, end-to-end transportation status, and capacity signaling enable proactive rerouting and faster recovery. Advanced analytics, AI-powered forecasting, digital twins, and scenario planning empower teams to forecast disruptions, test contingency plans, and quantify trade-offs between carrying costs and service levels. The outcome is a more resilient network capable of absorbing shocks rather than simply weathering them.

Complementary to technology and supplier strategies are disciplined inventory management strategies that balance safety stock with efficiency. By segmenting inventory, tuning reorder points, and aligning buffer stock with lead times, organizations can reduce stockouts while avoiding excessive carrying costs. Together, these measures address not just the symptoms of disruption but the root causes of persistent bottlenecks, supporting more reliable delivery performance and stronger overall resilience.

Frequently Asked Questions

What are the main drivers of supply chain bottlenecks in today’s global networks, and how can organizations mitigate them?

Supply chain bottlenecks stem from four interrelated areas: supplier risk and sourcing constraints, manufacturing capacity and downtime, logistics/transit capacity, and demand volatility. These drivers fuel supply chain disruption and logistics bottlenecks across ports, transport links, and facilities, driving higher landed costs and longer lead times. To strengthen supply chain resilience, act on: diversifying and regionalizing suppliers; boosting end‑to‑end visibility of inventory and capacity; building contingency stock for critical components; improving demand planning and scenario planning; optimizing logistics across modes; and adopting agile manufacturing through collaborative supplier planning.

Which inventory management strategies help reduce supply chain bottlenecks and improve throughput across a disrupted network?

Inventory management strategies should balance service levels with carrying costs while mitigating bottlenecks. Key actions include: optimizing safety stock and reorder points for critical components; improving forecast accuracy to align supply with demand; enhancing supply chain visibility to detect bottlenecks early; diversifying suppliers to reduce disruption risk; aligning procurement, production, and logistics with agile planning; and using scenario planning and digital tools to test contingency plans. Together, these inventory management strategies strengthen supply chain resilience against global supply chain challenges and help maintain steady throughput.

| Theme | Key Points | Impacts / Examples |

|---|---|---|

| Bottlenecks across nodes | Supply chain bottlenecks are persistent across production plants, ports, logistics networks, and labor markets, collectively throttling throughput. | Not isolated; affect overall flow and lead times; headlines reflect widespread pressure. |

| Current patterns | Three patterns drive bottlenecks: capacity limits in transportation/warehousing, demand volatility, and fragile supplier networks. | Any creak slows downstream processes; inventories rise; lead times extend. |

| Framework categories | Four categories: supplier risk/sourcing constraints; manufacturing capacity/downtime; logistics capacity; demand forecasting gaps. | Interacting factors create feedback loops and higher landed costs. |

| Industry impacts | Manufacturing line slowdowns; retail stockouts or excess safety stock; healthcare shortages; longer product cycles in tech. | Bottlenecks ripple globally, affecting inventory strategies and service levels. |

| Mitigation & resilience | Diversify suppliers; regionalize; increase visibility; contingency stock; improve forecasting; optimize logistics; embrace agile manufacturing and collaboration. | Reduces exposure, shortens cycles, strengthens resilience. |

| Technology & data | AI forecasting, digital twins, real-time sensors/IoT visibility; scenario testing. | Faster detection and actionable insights; proactive risk management. |

| Measuring progress | Cycle time, on-time delivery, forecast accuracy, inventory turnover, fill rate. | Data-driven feedback loops to monitor progress and refine strategies. |

Summary

Supply chain bottlenecks are a defining feature of modern business, shaping how organizations plan, source, manufacture, and move goods across geographies. In this descriptive overview, diversification of suppliers, real-time visibility, smarter inventory strategies, and resilient processes powered by advanced analytics help reduce vulnerability, shorten lead times, and sustain service levels even amid disruption. The objective is not to eliminate every bottleneck but to detect, adapt, and recover quickly when disruptions occur, maintaining competitive advantage in a complex global supply chain.